Photo Essay: Traveling with the Green Bay Packers

Written by Wes Hodkiewicz, packers.com

Team photographers Evan Siegle and Emma Pravecek follow Green Bay’s equipment staff on three road trips

GREEN BAY – The world of NFL equipment is a dutiful dance of detail and organization.

It’s a service-oriented occupation requiring focus, patience, and teamwork to ensure even the smallest stone isn’t left unturned. Ten times each season, equipment staffs plan, load, and ship everything a football team might need to play an NFL game on the road.

For 30 years in Green Bay, that responsibility has rested on the shoulders of Packers equipment manager Gordon “Red” Batty, who oversees a staff of four full-time equipment employees and more than a dozen associate staffers.

Each member of Batty’s crew is entrusted with set responsibilities during road trips. The complexity of the NFL demands a certain level of delegation, empowering individuals to take ownership of their area of expertise.

Assistant equipment manager Tom “T-Bone” Bakken handles everything related to the Packers’ coaching and support staff, including their clothing and sideline apparel. He’s also the point person for cleats and shoes, which are ordered every November for the following season.

Assistant equipment manager Bryan Nehring coordinates the loading and deployment of the semitruck that’s driven to the next opponent’s venue. He also organizes the bench area and sideline on gamedays.

Equipment assistants Tim Odea and Chris Kuehn prepare clothing and uniforms that’ll be ready for players in the visiting locker room once they arrive at the stadium. Odea oversees the locker room on gameday, while Batty is the go-to for the preparation and restoration of helmets.

Aiding the full-time staff are assistants Henry Broussard, Kevin Duffy, Isaak Fielding, Andy Gruber, Landon Koester, Alek Martinez, Austin Martinez, Aaron Parker, Shane Schick and Brett Treichel, and seamstresses Brenda Hannon, Deb Matson, Dawn Niemi, Cheryl Zehms, Lori Lessmiller, Chris Kniep and Kendra Katers.

Earlier this season, Packers team photographers Evan Siegle and Emma Pravecek followed Batty and his staff as they prepared the team’s equipment for three consecutive road trips to Las Vegas, Denver, and Pittsburgh over the span of five weeks.

Prior to every road trip, Odea and longtime equipment assistant Shane Schick organize players’ personal bags for each trip, including any shirts, shoes, and knee/thigh pads that players will utilize during the game. The equipment staff also works with the Packers’ trainers to ensure any braces and harnesses for specific players make the trip. All these items will be laid out in the players’ lockers when they arrive for the game.

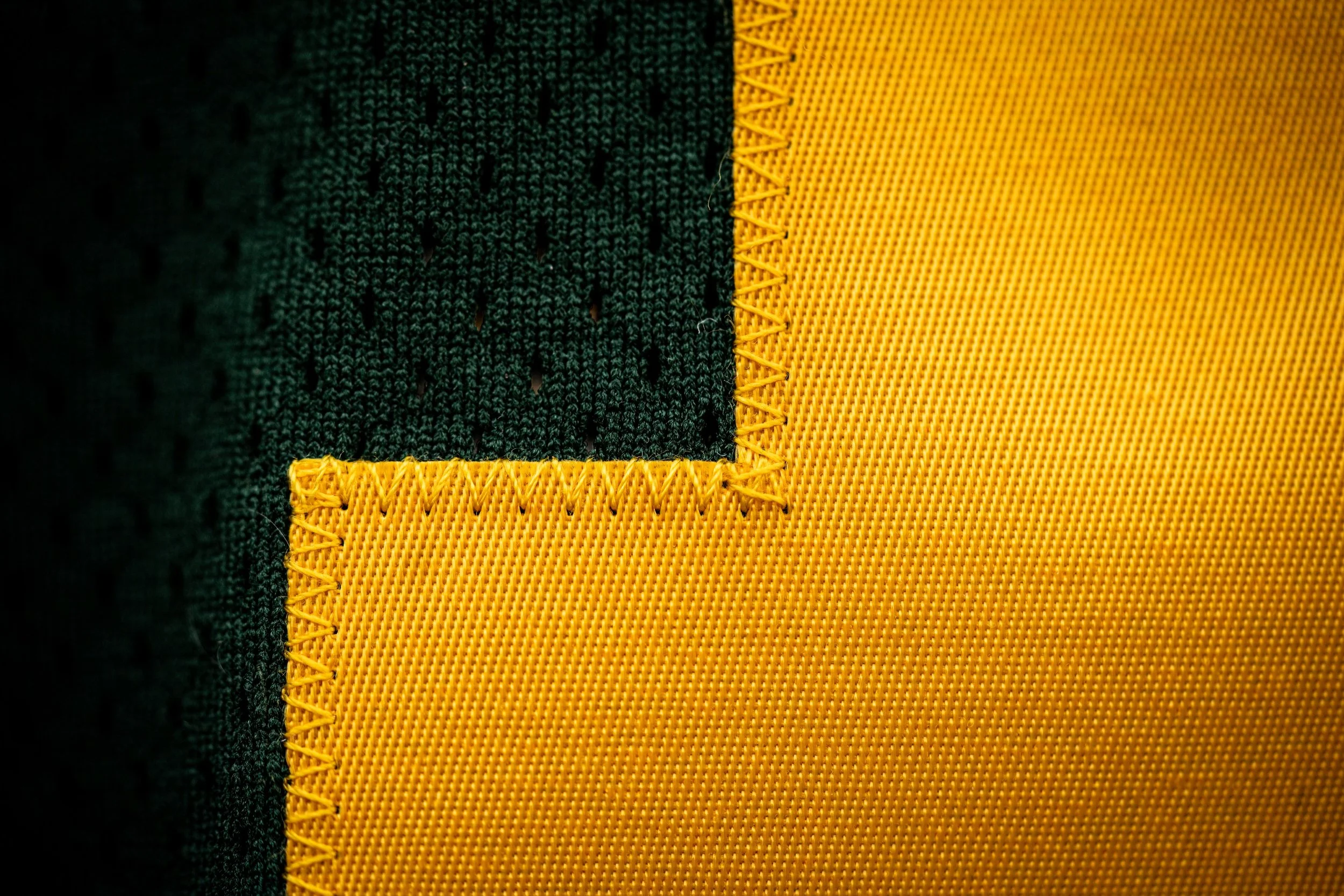

What the average fan sees on gameday is just the tip of Green Bay’s equipment iceberg, as the team also packs backup uniforms for every road trip. Most tears can be repaired with sewing and shoelaces, but in the rare case a jersey is damaged beyond repair, the equipment staff can quickly get the backup jersey fitted on a player’s shoulder pads through the use of a slider. The backup jerseys are packed in a separate case with extra pants. In case of a late switch of uniform colors, the Packers also bring a set of green jerseys with them.

The primary jerseys, kept in a separate trunk, are treated with great care – steamed inside the fitting room at Lambeau Field and then laid out on hangers (five in one direction and five the other way).

Batty and Kuehn work together to make sure every primary jersey is accounted for and placed in the trunk. Batty calls out jersey numbers and Kuehn checks off names on a list. The sheet is a color-coded system based on active roster (orange), practice-squad elevations and also jerseys already fixed to shoulder pads (green) before the team leaves.

Bakken handles readying all apparel related to the Packers’ coaches and support staff. He checks in with coaches on Thursdays for any special clothing requests and makes sure those items are packed on Friday. Some of those trunks are loaded on the plane and others go on the truck.

The team flies with everything it absolutely needs to play the game, including the helmets, shoulder pads, shoes, and equipment bags with all the necessary items each player needs, but it also utilizes a semitruck that plays a vital role in getting Green Bay’s equipment to and from road games with great haste thanks to drivers Jason Dunn and Rob Miller.

The Packers were among the first to transport equipment across the country. The process of loading and unloading trucks is one Bakken likens to a “big game of 3-D Tetris.” In addition to equipment cases, the truck also transports trunks for the training staff, strength and conditioning coaches, and communications and digital departments. Working in 10-hour shifts, Dunn and Miller can drive nonstop to get the Packers’ equipment anywhere in the country in a day or two.

When the plane lands, the truck is there to continue onto the stadium and setup begins taking place, with the trunk for jerseys, four helmet bins, four shoulder-pad bins and four bins for equipment bags.

Lockers are organized by offense and defense, in numerical order. Name plates put up, while each player bag placed in the locker. Once all bags are checked off, Odea and the support staff lay out clothing and set shoulder pads up. It’s roughly a 1½-hour process.

A week of thorough prep goes into the helmets, which Batty oversees. If a helmet needs to be repaired, players will be summoned to the fitting room midweek to make sure it’s back in working order and fits properly. Batty examines every inch of the helmet on gameday. Nobody else touches the helmets and they aren’t placed in the lockers until Batty signs off.

The equipment staff runs another checklist on gamedays. Jerseys are hung in lockers while sideline clothes are laid out for inactive players. The Packers take measurements of players at rookie minicamp, which are used to tailor jerseys and pants. When new pants are needed, Odea jots down a player’s measurements on a small piece of paper and assistant Henry Broussard hangs those instructions on the garment for the seamstresses.

Once the season begins, the need to produce and maintain jerseys is non-stop. The Packers order most directly from the factory, with seamstresses performing whatever adjustments players desire on the jersey. What’s more, the equipment staff is also responsible for outfitting the Packers’ 17 practice-squad players during the week.

There can be a lot of ebb and flow with the practice squad. For example, six players on Green Bay’s current practice squad didn’t start the season with the Packers. Game jerseys for new players are produced at Ripon Athletic and Green Bay seamstresses do the final alterations.

Now in his 38th full-time season with the Packers, Nehring leads one of the most essential parts of the preparation process every Saturday in the equipment storage room. Inside those walls, Nehring will inflate the gameday footballs to the required 13 pounds per square inch (with a half-pound allowance on either side of that) and Green Bay’s starting quarterback – now Jordan Love – will feel the footballs and give his go-ahead on the dozen that will be selected for use in the game.

The footballs are sorted into two bags for travel. Once the team arrives, Nehring will check the air before assistant Kevin Duffy presents the footballs to the referees for inspection two hours before the game. Thousands of gameday footballs have passed through Nehring’s hands, including every touchdown Brett Favre, Aaron Rodgers and Love ever threw as the Packers’ QB.

While Dunn and Miller drive the semi to the next game, local driver Mark Massonet hauls the rest of the team’s equipment from Lambeau Field to the team plane at Austin Straubel Airport. Bins are tilted wheels up not only to prevent them from falling over but also to maximize space under the plane.

Once the team arrives at the opposing stadium on gameday, the equipment staff will open locked cargo and set up lockers. Any piece of apparel a player could want is available. If the temperatures are cooler, Odea might set out an extra thermal top in lockers. The players can choose to wear it or not wear it, but it will be available to them.

The Packers travel with their own set of custom-logo chairs, a total of 120 housed in five trunks.

One of Batty’s core beliefs is the helmet is the most important piece of equipment a player will ever wear and treats it as such. The Packers’ longtime equipment manager uses four checkpoints to determine if helmets are ready for the game: decals, facemask, shields, and stickers (e.g. Crucial Catch, Salute to Service, and Inspire Change). He carefully inspects each helmet before Odea hangs it in the locker. The Packers bring the players’ backup helmets on the road, too, which are sorted six to a bag.

In addition to setting up the locker room, the Packers’ equipment staff assists with the preparation for the helmet speakers. The team uses five offensive and five defensive modules during the practice week, but most are removed before the Packers leave for a game. For example, safeties might use them in practice to aid communication but only the inside linebacker wearing the green dot has one in his helmet on gameday. Three hours before the game, the Packers will install the communication devices into the primary and backup helmets belonging to Love and backup QB Sean Clifford. There also is a backup helmet for the team’s emergency quarterback.

Likewise, the “Mike” linebacker will have a primary and backup helmet with the module. The Packers also will keep backup helmets with communication devices for two other defensive players in case of injury or emergency. The equipment staff will set the volume to each player’s preferences – usually louder on the road and quieter for Love when playing at Lambeau.

To fine-tune the headsets, members of the Packers’ equipment and football technology staff will walk around the perimeter of the field to make sure the helmets are working properly in every area of the playing surface. Every team has its own philosophy, but the idea is if the modules work on the outside of the field, then everything also will work on the interior.

The modules are installed in the locker room, but the equipment staff doesn’t plug in the batteries until the headsets are on the sideline to give the batteries a full life. Manager of football application development Eric Prosise, who tests the audio from Head Coach Matt LaFleur’s headset, brings life to what can be a monotonous process once the testing begins.

In lieu of a traditional, “Testing, testing, 1, 2, 3, hey, hey” reverberation, Prosise instead reads off scores and statistics from other games if the Packers are playing a late game. If it’s a noon start, Prosise either recounts Packers history or offers facts about the stadium, often off the top of his head. On defense, football technology assistant Joe Reuter tests defensive coordinator Joe Barry’s headset from the coaches’ booth near the press box.

While the equipment staff has ample time to load the semi for departure, the window is only 45 minutes to an hour to get the truck ready for the return trip to Green Bay after the game. Some trunks, including clothing, are loaded at halftime with a “host” staff of six assistants available to help get bins and carts to Dunn and Wilson, who put the equipment puzzle back together again inside the 18-wheeler.

Once everything is back in Green Bay, the equipment staff begins washing laundry and making repairs.

After each practice and game, equipment assistants Aaron Parker and Austin Martinez will clean helmets and shields, while also checking for damage to facemasks and decals. The process takes approximately two hours following practices and four hours before and after games.

Helmets and facemasks are scrubbed and cleaned. Even the chinstrap is vastly different from when Rodgers became a starting QB in Green Bay 15 years ago. Roughly half the Packers’ roster wears Oakley shields.

A sign of those times, after the Packers’ Week 10 game in Pittsburgh, Aaron and Austin had the added duty of removing the decals from helmets in preparation for the team wearing its “50s Classic” uniforms game against the Los Angeles Chargers. The growing number of specialty games presents challenges because of all the slight on-field adjustments to uniforms and also the sideline clothing that must be ready for gameday.

Back in the fitting room, the equipment team has cubby holes for each player’s helmet, facemask and guardian caps for practice. After modern decals are removed, each helmet is fitted with a special grey facemask for the game. There are five masks most Packers players will use, but that number could swell to eight depending on the helmet. Kuehn takes care of ordering and arranging masks for players.

The work is rarely over and once the game ends, the process begins again. In this field, one eye is always turned to the future, while the other makes certain every “I” is dotted and “T” is crossed in the present.